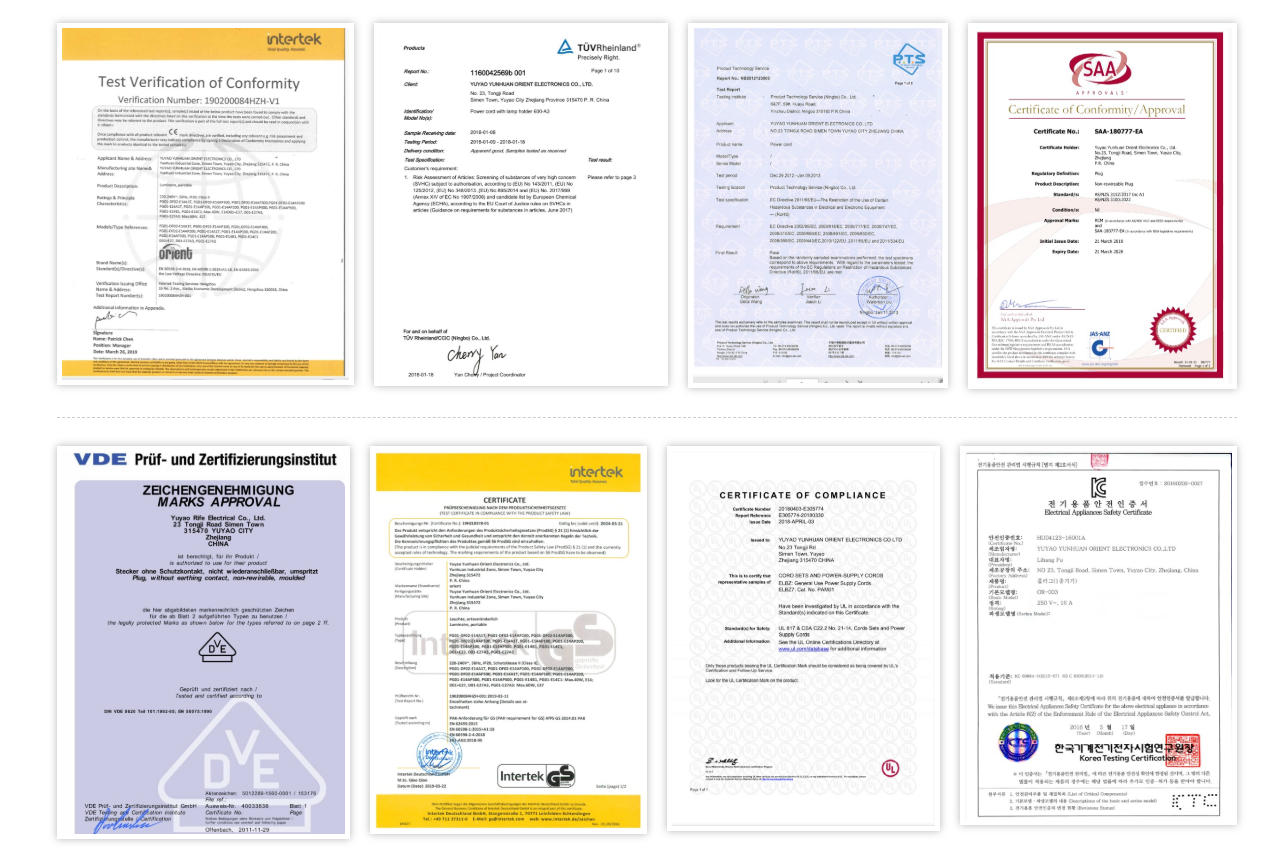

For OEMs sourcing power cords globally, the stakes are incredibly high. A single component failure can cascade into costly product recalls, brand damage, legal liabilities, and severed customer trust. In this high-risk environment, partnering with suppliers holding robust international safety certifications, particularly UL and VDE, is not just a best practice – it’s a fundamental risk mitigation strategy. Suppliers like Yuyao Yunhuan Orient Electronics Co., Ltd. (Yuyao Rife Electrical Co., Ltd.), equipped with 7+ critical global certifications (including UL, VDE, CE, CCC, GS, SAA, RoHS), provide OEMs with a vital shield against these pervasive sourcing dangers.

The High Cost of Non-Compliance: Beyond Recalls

The consequences of sourcing non-compliant power cords are severe and multifaceted:

1.Market Access Denied: Products lacking mandatory certifications like UL for North America, VDE/GS for Europe, CCC for China, or SAA for Australia are barred at the border. This results in shipment delays, seizure, and lost revenue.

2.Catastrophic Recalls & Fines: Non-compliant cords are a primary cause of electrical fires and safety hazards. Regulatory bodies (CPSC, RAPEX, etc.) impose massive fines for violations, and the cost of a global product recall – logistics, replacements, legal fees, brand remediation – can cripple a business. UL estimates that non-compliant electrical components contribute significantly to product recalls annually.

3.Irreparable Brand Damage: News of safety incidents spreads rapidly. Consumer trust, painstakingly built over years, evaporates overnight. Rebuilding a tarnished reputation is often impossible or prohibitively expensive.

4.Legal Liability & Lawsuits: Injuries or property damage traced back to a faulty power cord expose the OEM to devastating lawsuits and settlements.

5.Supply Chain Disruption: Discovering non-compliance mid-production or after shipment halts operations, strains relationships with retailers, and creates inventory chaos.

UL & VDE Certification: The Gold Standard in Risk Mitigation

Certifications like UL (Underwriters Laboratories) and VDE (Verband der Elektrotechnik) represent far more than just a mark on a cord. They are rigorous, ongoing assurances:

Stringent Design & Material Verification: Products are tested against extreme conditions – overload, abnormal heat, flexing, strain relief – far exceeding normal use. Materials must meet strict flammability and electrical properties.

Manufacturing Process Oversight: Certification bodies conduct regular, unannounced factory audits (like UL’s Follow-Up Services). This ensures the certified product rolling off the line today matches the tested sample and meets all standards. It verifies consistent quality control processes are in place and followed.

Traceability & Accountability: The certification mark is a direct link back to the manufacturer and the specific tested product type, providing crucial traceability in case of issues.

Global Recognition: While UL and VDE are region-specific (North America and Germany/Europe respectively), their rigorousness makes them globally respected benchmarks. Suppliers holding both demonstrate a commitment to the highest universal safety principles.

Choosing the Right Certified Partner: Beyond the Logo

Possessing certifications is essential, but OEMs must look deeper to truly mitigate risk:

1.Scope & Depth of Certification Portfolio: Does the supplier hold all necessary certifications for your target markets (UL, VDE, CCC, SAA, etc.)? Yuyao Yunhuan Orient Electronics demonstrates this commitment with its 7+ global certifications (UL, VDE, CE, CCC, GS, SAA, RoHS, REACH, NF).

2.Integrated Quality Management: Certifications must be underpinned by a robust, living quality system like ISO 9001:2015, which Yuyao Yunhuan Orient Electronics maintains, covering design, manufacturing, and maintenance. This ensures systemic consistency.

3.In-House Testing & Process Control: Reliable suppliers invest heavily in advanced production and testing facilities. Yuyao Yunhuan Orient Electronics conducts rigorous safety testing on 100% of products before shipment, alongside production inspections, guaranteeing every cord meets spec.

4.Proactive R&D & Customization: Standards evolve, and OEMs need unique solutions. A strong in-house R&D team, like the one at Yuyao Yunhuan Orient Electronics, allows for rapid development of custom cords and molds, ensuring new products are designed compliantly from the outset. Their offer of free samples within 3 days accelerates prototyping and validation.

5.Transparency & Responsiveness: Can the supplier readily provide up-to-date certification documentation? Do they communicate proactively about compliance changes or potential issues?

6.Operational Reliability: Consistent on-time delivery is crucial. Yuyao Yunhuan Orient Electronics’ strategic location near the Ningbo and Shanghai ports significantly reduces lead times and logistics costs, enhancing supply chain resilience. Their 7500 sqm facility supports scalable production.

Yuyao Yunhuan Orient Electronics: Your Certified Risk Mitigation Partner

Understanding that quality is the non-negotiable foundation of enterprise development, Yuyao Yunhuan Orient Electronics Co., Ltd. has built its reputation as a global supplier of higher-quality power cords for home appliances by rigorously adhering to international standards. Our comprehensive suite of 7+ global safety certifications (UL, VDE, CE, CCC, GS, SAA, RoHS, REACH, NF), coupled with our ISO 9001:2015 certified quality management system, provides OEMs with the assurance they demand.

We go beyond certification. Our advanced production and testing facilities enable 100% safety testing before shipment. Our dedicated R&D team delivers custom power cord solutions and rapid prototyping (free samples in 3 days). Combined with competitive pricing, stringent quality control, and efficient logistics via Ningbo/Shanghai ports, we offer OEMs a truly de-risked sourcing solution.

Mitigate Your Sourcing Risk Today

Don’t leave the safety, compliance, and reliability of your products to chance. Partner with a power cord supplier whose commitment to global certifications and quality is unwavering.

Contact Yuyao Yunhuan Orient Electronics Co., Ltd. to discuss how our 7+ global certifications and robust capabilities can secure your supply chain and protect your brand.

Why this article works for SEO and B2B Lead Generation:

Keyword-Rich Title & Headings: Includes primary keywords (“UL/VDE-Certified,” “Power Cord Suppliers,” “Mitigate Sourcing Risks,” “OEMs”) and secondary (“Global Certifications”).

1.Targets Pain Points: Immediately addresses the severe consequences (recalls, fines, brand damage) that keep B2B procurement managers awake at night, establishing relevance.

2.Establishes Authority: Explains why UL/VDE are important (rigorous testing, audits, traceability), positioning certifications as essential risk mitigators, not just checkboxes.

3.Clear Value Proposition: Links the supplier’s specific strengths (7+ certs, ISO 9001, in-house testing, R&D, logistics) directly to solving the buyer’s problems (risk reduction, compliance, reliability, speed).

4.Company Integration: Weaves Yuyao Yunhuan Orient Electronics’ credentials, capabilities, and USPs (certifications, testing, R&D, location, free samples) naturally into the narrative as the solution to the risks discussed. Mentions the company name strategically early and prominently.

5.Action-Oriented Conclusion: Provides a clear call to action for risk-averse OEMs.

6.B2B Focus: Uses formal language, focuses on operational and financial risks, compliance, and supply chain reliability relevant to business decision-makers.

7.Length & Depth: Exceeds 1000 characters, providing substantial content for SEO and demonstrating expertise.

Post time: Jun-12-2025